Carbon Fiber Prepreg Market | Exactitude Consultancy Reports

#Exactitudeconsultancy #marketresearch

Exactitude Consultancy Latest Published

Carbon Fiber Prepreg Market Overview

The global carbon fiber prepreg market is expected to grow at 8.0% CAGR from 2020 to 2029. It is expected to reach above USD 21.8 billion by 2029 from USD 9.62 billion in 2022.

A reinforcing fabric that has been pre-impregnated with a resin system is referred to as “prepreg” in common usage. The appropriate curing ingredient is already present in this resin system (usually epoxy). As a result, no additional resin is required to prepare the prepreg for laying into the mold. Pressure and heat must be applied in conjunction for the laminate to cure.

Epoxy, phenols, and thermoplastic resins like PEEK are used to create carbon fiber prepregs from carbon fibers. Because prepreg has a high strength-to-weight ratio, strong resilience to corrosion and fatigue, and excellent fire resistance, it is appropriate for use in commercial and industrial settings. Carbon fiber prepreg is created by pre-impregnating fibers, notably those made of glass, carbon, and aramid, onto a matrix material.

Segment Analysis

The global carbon fiber prepreg market is segmented based on resin type, manufacturing process and end-use industry. By resin type, the market is bifurcated into epoxy, phenolic, thermoplastic, bismaleimide, polyimide, and others. By manufacturing process, the market is bifurcated into hot melt, solvent dip. By end-use industry, the market is bifurcated into aerospace & defense, wind energy, sports & recreation, automotive, and others.

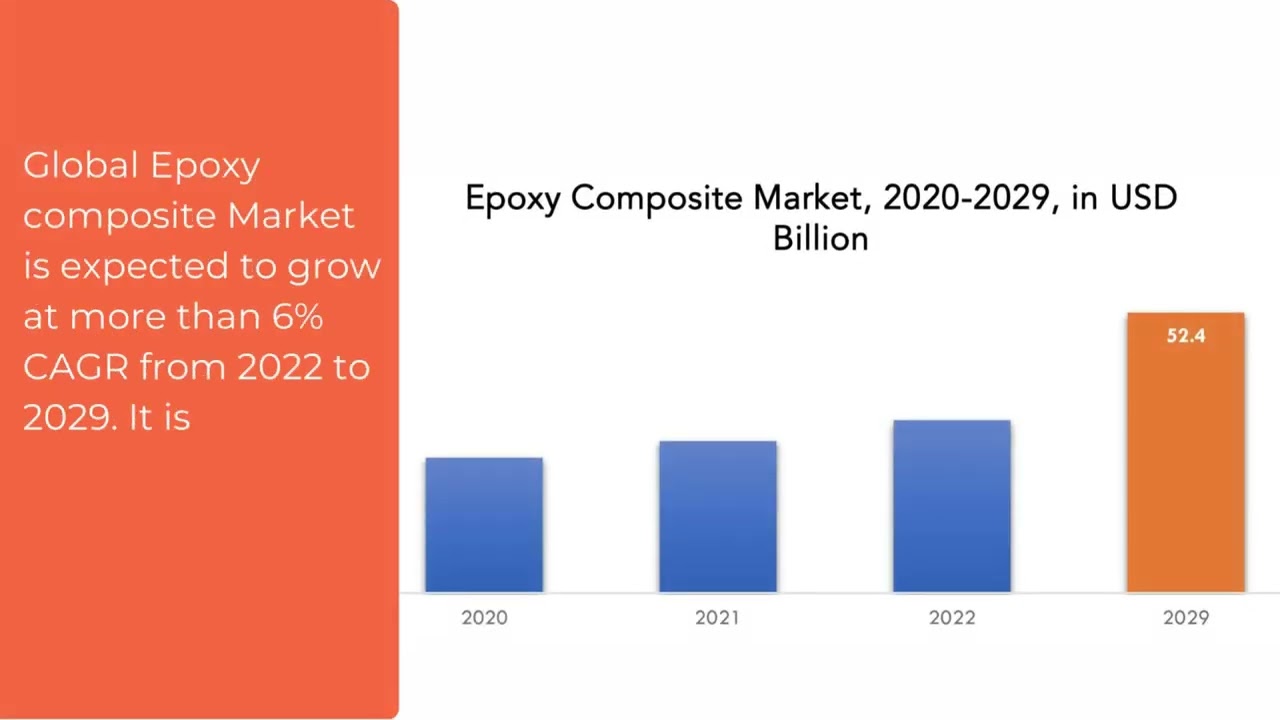

Based on the resin type epoxy resin accounted for the largest market in the Carbon Fiber Prepreg, Due to its extensive use in the aerospace & military, automotive, sports & leisure, wind energy, and other industries, epoxy resins control the majority of the dry carbon fiber market. Epoxy resins are particularly expensive because of how expensive it is to process them for different purposes towards the end of their life. Epoxy resins are extremely durable, though, due to their strong, interlinking molecular structure, inert chemical makeup, and resistance to UV and chemical attacks. Automotive and aerospace & military industries are the two main businesses that use epoxy resin with carbon fiber reinforcing. Additionally, compared to other thermoset resins, it cures more quickly, making it the thermoset resin of choice for automakers.

To Know more: https://exactitudeconsultancy.....com/reports/14386/ca

Not what you were looking for? Go through similar reports by The Exactitude consultancy:

https://exactitudeconsultancy.....com/reports/947/semi

https://exactitudeconsultancy.....com/reports/1076/dis

Contact us@ sales@exactitudeconsultancy.com